Analytical Validation of Diesel Engine Components through FEA

Analytical Validation of Diesel Engine Components through FEA

Customer background: US based customer who is a manufacturer of wide range of diesel and gasoline type engines and diesel generators operating in varied applications and geographies – We supported this customer on a power uprate program that was aimed at increasing the engine power for genset application with minimal design changes.

Objective of the project: To validate the major components and sub-systems of the diesel engine (uprated with higher combustion pressure) for the given operating as well as accelerated abusive testing conditions through Finite Element Analysis (FEA).

Key challenges:- To capture physics appropriately for simulating both operating as well as accelerated testing conditions by deploying appropriate analytical methods.

- Correlation of the analyses results with past experimental test data for the baseline design to verify the approach used.

- Program involved much larger dependence on analytical validation for making design decisions thus calling for accurate simulations to avoid failures in testing or field.

- Design optimization for weight for gaining significant cost benefit for the product which sells in high volumes.

4Dimensions Infotech supported the entire analytical validation and optimization of the Engine components such as Crankcase (Cylinder Block), Cylinder Head, Exhaust Manifold, and other Engine peripheral components (CAC / Air Cleaner / Charging Alternator mounting brackets etc.) through Finite Element Analysis (FEA).

- Three engineers worked on this project for the period of five months. Analysis was done in ANSYS FEA software (ANSYS-Workbench and APDL).

- High Cycle Fatigue (HCF) durability analysis of the Crankcase assembly and Cylinder Head.

- Thermal duty cycle and Low Cycle Fatigue (LCF) life assessment of the Exhaust Manifold and Cylinder Head.

- Vibration (Modal/Pre-stressed modal) analysis of engine peripheral components.

- Quicker to market product due to significant reduction in testing time and cost due to design optimization through analytical techniques.

Engineering Design and Development Solutions for Gensets

Customer background: European company manufacturing engines and gensets for power generation and industrial applications, playing in Indian market along with an Indian partner company. We supported this customer in new genset design and development programs for India and Asian markets.

Objective of the project:- Design and develop gensets for high kVA rating for India and Asian markets.

- Develop cost-effective solution with effective standardization of systems with product for the rest of the markets.

- Optimization of the design for manufacturing cost while having sub-system standardization with global product.

- Meet all stringent performance and regulatory requirements.

- Modular design to accommodate multiple alternator combinations and two kVA ratings.

- Requirement to package the silencer inside the enclosure while optimizing the footprint.

- Meet stringent timelines to ensure the product is launched fast in the market.

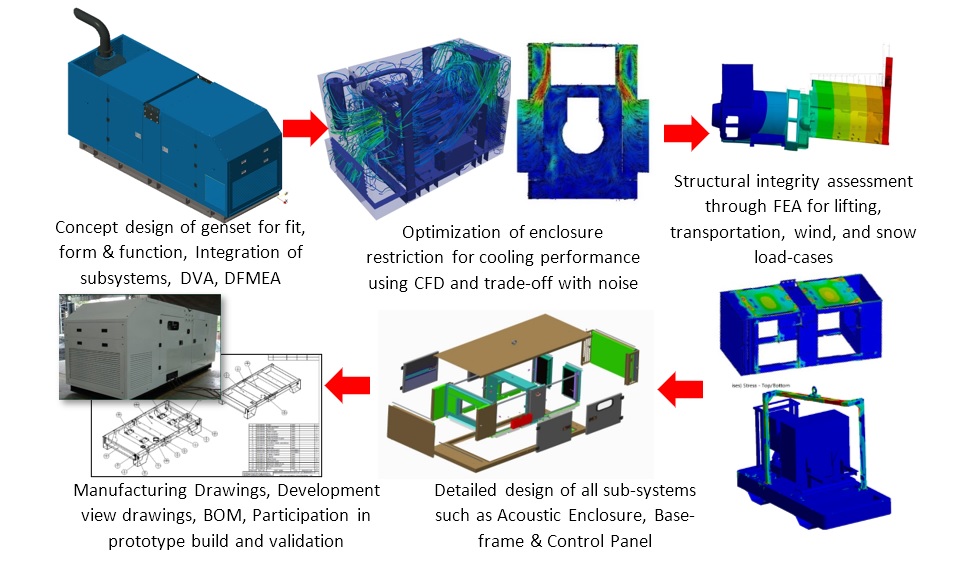

4Dimensions Infotech deployed a competent team of 6-8 engineers which was intensely involved in the entire program for more than 1 year and took responsibility of the complete product design and analytical verifications, and also provided support during prototype building and testing. Activities supported by 4Dimensions Infotech team for multiple genset rating were:

- Concept and detailed design of the components and sub-systems of Genset such as base-frame, acoustic enclosure, Control panel, engine mounts, mounting brackets for air cleaner, silencer and fuel filter, etc using Creo-Parametric CAD tool.

- DFMEA of the overall genset and inputs to DVP&R.

- Structural integrity verification using Finite Element Analysis (FEA) for Stress and Vibration including system-level torsional vibration assessment. Assessment for lifting, transportation, snow load, wind load and seismic conditions using ANSYS FEA tool.

- Computational Fluid Dynamics (CFD) analysis for obtaining trade-off between cooling performance and noise.

- Assessment of design for manufacturability, assembly and serviceability considerations.

- Creation of the detailed manufacturing drawings, installation drawings and assembly procedures, performing tolerance stack-up calculations.

- Support for proto build, addressing manufacturing feedback and validations.

Engineering Support to US Customer in Energy Sector

Customer background:Customer had embarked upon this program with following key objectives:

- Design and develop an aero-derivative land-based gas turbine to provide energy solutions to its global customers.

- Set the industry standard for comprehensive assessment, repair, upgradation and optimization for aero-engine for land based power generation applications.

- Carry out the thorough analysis of aeroderivative turbine equipment and redesign the components, sub-systems to meet the specified performance and design requirements.

- Durability assessment of components and sub-systems for Low Cycle and High Cycle Fatigue (LCF/HCF) under varied operating duty cycles

- Optimization of the design from manufacturing cost considerations

- Carry out detailed engineering activities while optimizing the design and development costs.

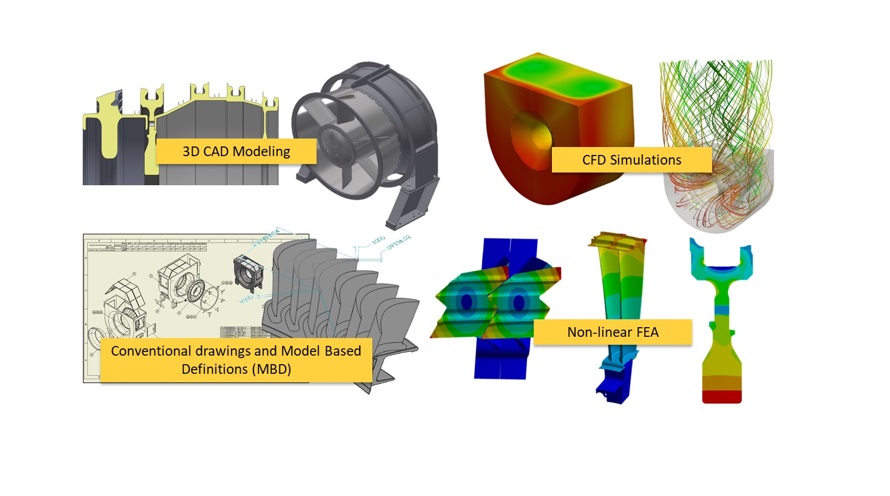

4Dimensions Infotech deployed a competent cross-functional team of 14-16 engineers for more than 2 years to support a wide range of activities over the complete product design and development cycle. Our support to the customers consisted of activities such as:

- Designing and creating the parametric models of components and sub systems such as rotors, blades and casings

- Creating design definitions using the model-based definitions (MBDs) approach and manufacturing drawings as necessary

- CFD analysis for flow and heat transfer predictions

- Structural integrity assessment through FEA for stress and vibration including rotor dynamics analysis

- Durability calculations for Low and high cycle fatigue conditions (LCF / HCF)

- Optimization and DoE studies

- Technical documentation and Reports

- Technical publications

Customer was delighted with the technical and project management capabilities demonstrated by 4Dimensions Infotech team including regular updates and communication in a professional manner.

.jpg)